Mig Welding Gas Pressure Chart. For many applications youll be using 100 argon. Compared with argon helium provides better side wall penetration and higher welding speeds by generating a more energy-rich arc. Hydrogen Hydrogen H 2. The process is more sensitive to arc length variations with helium as a shielding gas and the arc is more difficult to strike when TIG welding.

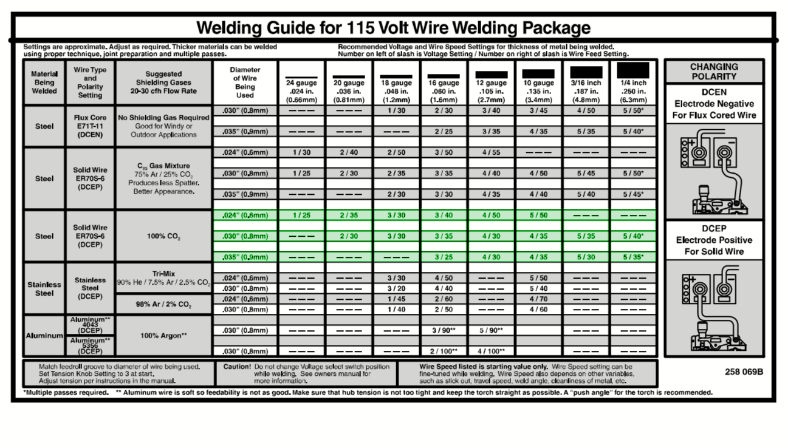

MIG provides the controlled supply of welding wire to the point to be welded. When youre MIG welding and using solid welding wire and shielding gas. If your welding thick plate with different profiles you may need to increase the pressure to protect the root weld while it solidifies. And that it has a clean connection to metal. When using 75 Argon and 25 CO2 gas. The optimal gas pressure varies a little but it should be around 15-25 CFH.

If your welding thick plate with different profiles you may need to increase the pressure to protect the root weld while it solidifies.

MIG welding also known as GMAW Gas Metal Arc Welding demands a shielding gas is used. But there are different mixes to consider with helium for different metals and thicknesses as well see chart. Tig Welding Shielding Gas Tips. Mon Shielding Gases For Arc Welding Mig welding gas settings chart lewisburg district umc 7 for improving mig welding tregas and bernard mig welder settings for various metal thickness s mig welding and techniques for ners mig welding settings chart metric lewisburg district umc. A shielding gas covering for your weld is fundamental to MIG Metal Inert Gas welding. MIG Welding Gas Pressure For most gas regulators the gas pressure PSI from your gas flow regulator or pipeline is set at a minimum of 25 PSI and as high as 80 PSI.