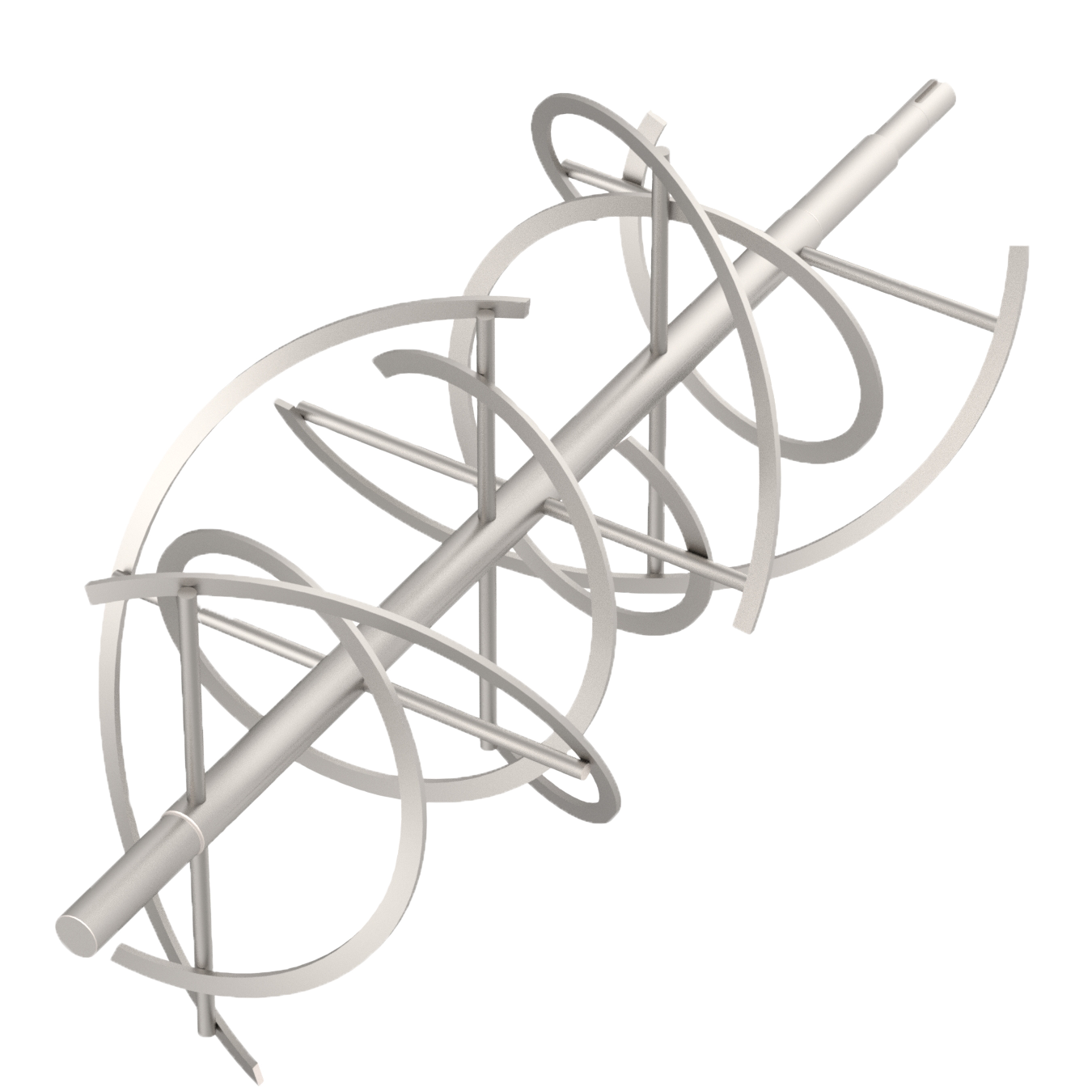

Horizontal Ribbon Mixer Design. A small section of the end directly above the shaft has a removablebolted in place section. For a fact SaintyCo RB Ribbon Mixer is an industry standard for highly efficient and reliable horizontal ribbon mixer. Which specifies a minimum 14 SF. While mixers come in many shapes sizes and levels of sanitation this article will focus on general horizontal configurations and examine the following three key elements.

The ribbon blender is one of. They consist basically of a trough-shaped shell usually 2 to 3 times longer than it is wide with a semicircular bottom fitted with a horizontal longitudinal shaft on which are mounted arms supporting a combination of ribbon blades paddles or helical screws set. This combination promotes fast and thorough blending. 1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 21-1 Direct-drive portable mixer. FEATURES Complete range of mixers available such as Plough Ribbon. All gear reducers selected are designed to AGMA Class 2 gearing requirements.

Ribbon Blender also named ribbon mixer is a basic industrial mixing machine.

All gear reducers selected are designed to AGMA Class 2 gearing requirements. The most common access features for ribbon blenders is to have hatches on top of the mixer with sometimes the possibility. The horizontal ribbon mixer design come with a lot of lush features that enhance efficiency. The Ribbon Blender does homogenous mixing of powder and semi-wet material of different densities. Go through this list of batch mixing system design considerations when working with horizontal ribbon mixers or other dry solids mixers and make sure your mixer works at optimal efficiency. FEATURES Complete range of mixers available such as Plough Ribbon.