Chloride Stress Corrosion Cracking Duplex Stainless Steel. 205 - 212 101016jcorsci201311028. Chlorides are easily concentrated. 80 2014 pp. Often this problem can be solved by the use of duplex stainless steels.

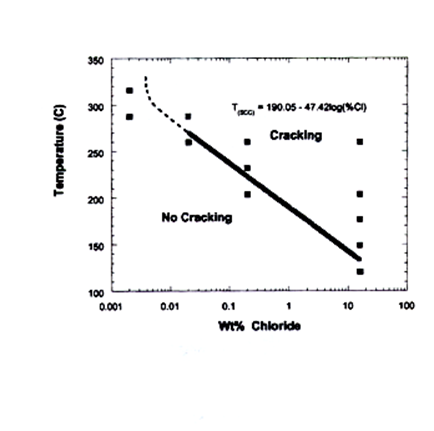

Chloride Stress Corrosion Cracking The greatest corrosion advantage for duplex stainless steels is their improved resistance to CSCC when compared to the austenitic grades. 205 - 212 101016jcorsci201311028. One note of caution. Duplex stainless steel having attractive combination of austenitic and ferritic properties is being used in industry such as petrochemical pulp and paper mills. Following failures of duplex stainless steel in 20012002 resulting from chloride stress corrosion cracking the Health and Safety Executive commissioned a review of the offshore operation of. Stress corrosion cracking of LDX 2101 duplex stainless steel in chloride solutions in the presence of thiosulphate Corros.

Chloride Stress Corrosion Cracking The greatest corrosion advantage for duplex stainless steels is their improved resistance to CSCC when compared to the austenitic grades.

Increasing nickel content above 18 to 20 or the use of duplex or ferritic stainless steels improves resistance to CSCC. Of the types of environmentally assisted cracking of austenitic. Austenitic stainless steel may be susceptible to chloride stress corrosion cracking CSCC. Although no stainless steel grade is totally immune to chloride SCC the relative resistance of stainless steels varies substantially. It is thought to start with chromium carbide deposits along grain boundaries that leave the metal open to corrosion. Chloride induced stress corrosion cracking in standard austenitic stainless steels viz.